Let's delve into the properties and applications of 90 Degree Elbows. Understanding these elements will ensure that your products and projects run smoothly and efficiently.

Table of Contents

- Properties and Uses of 90 Degree Elbow

- 90 Degree Elbow Specifications

- SS 90 Degree Elbow Dimensions and Size Chart

- Aluminum 90 Degree Elbow Weight Chart

- 90 Deg Elbow Materials

- Stainless Steel 90 Degree Elbow Pressure Rating

- Copper 90 Degree Elbow Dimensional Tolerance

- 90 Degree Elbow Angularity Tolerances

- 4 inch 90 degree elbow Chemical and Mechanical Properties

- Types of 90° Elbows

- SS 90 Deg Elbows Size Chart

- Advantages of 90 Degree Elbow

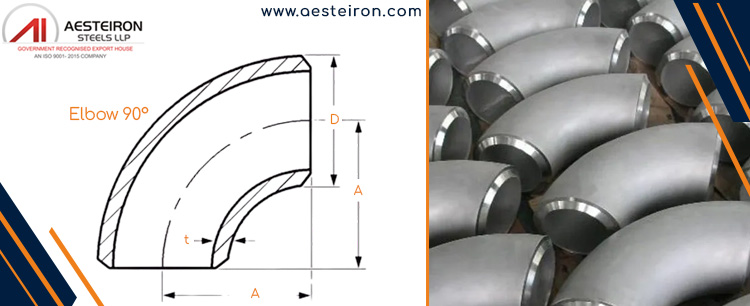

Properties and Uses of 90 Degree Elbow

Properties:

- 90-degree bend

- Redirects flow at a right angle

- Available in various sizes

- Matches different pipe diameters and flow rates

- Pressure ratings depend on material and design

- End types: threaded, welded, or flanged

- Radius: long radius, short radius

Applications:

Change the direction of a pipeline

Manage the flow of liquids and gases

- Oil and gas refineries

- Chemical plants

- Plumbing

- Power plants

- HVAC systems

90 Deg Elbows Are Manufactured According to ASME B16.9 Standards

The ASME B16.9 standard has been developed by the American Society of Mechanical Engineers. It applies to industrial buttweld fittings and covers pressure ratings, size, material, marking, dimensions, surface finishes, final preparation, fabrication testing, and tolerances.

90 Degree Elbow Specifications

| 90 Degree Elbow Size Range |

|

|---|---|

| Standards |

|

| Manufacturing Standards |

|

| Stainless Steel 90 Degree Elbow Thickness |

|

| 4 Inch 90 Degree Elbow Coating |

|

| Aluminum 90 Degree Elbow Type |

|

| Copper 90 Degree Elbow Radius |

|

Explore the Sizes and Dimensions of Stainless Steel 90 Degree Elbows

These elbows are manufactured in several grades of stainless steel, primarily 304 and 316 SS. They offer excellent corrosion resistance, high strength, durability, aesthetic appeal, and require minimal maintenance.

Here are the sizes and dimensions of SS 90 degree elbows.

SS 90 Degree Elbow Dimensions and Size Chart

| inch | D | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 3 1/2 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ND | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 90 | 100 | 125 | |

| mm | 21,34 | 26,67 | 33,40 | 42,16 | 48,26 | 60,32 | 73,02 | 88,90 | 101,60 | 114,30 | 141,30 | |

| Center to center | O | 76,20 | 57,15 | 76,20 | 95,25 | 114,30 | 152,40 | 190,50 | 228,60 | 266,70 | 304,80 | 381,00 |

| Radius | A | 38,10 | 28,57 | 38,10 | 47,60 | 57,15 | 76,20 | 95,25 | 114,30 | 133,35 | 152,40 | 190,50 |

| Back to face | K | 47,62 | 42,86 | 55,56 | 69,85 | 82,55 | 106,40 | 131,80 | 158,75 | 184,15 | 209,55 | 261,90 |

| Center to end | B | 15,87 | 11,11 | 22,22 | 25,40 | 28,57 | 34,92 | 44,45 | 50,80 | 57,15 | 63,50 | 79,38 |

| inch | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 28 | |

| ND | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 700 | |

| mm | 168,27 | 219,07 | 273,05 | 323,85 | 355,60 | 406,40 | 457,20 | 508,00 | 558,80 | 609,60 | 711,20 | |

| Center to center | 457,20 | 609,60 | 762,00 | 914,40 | 1066,80 | 1219,20 | 1371,60 | 1524,00 | 1676,40 | 1828,80 | 2133,60 | |

| Radius | 228,60 | 304,80 | 381,00 | 457,20 | 533,40 | 609,60 | 685,80 | 762,00 | 838,20 | 914,40 | 1066,80 | |

| Back to face | 312,70 | 414,30 | 517,50 | 619,10 | 711,20 | 812,80 | 914,40 | 1016,00 | 1117,60 | 1219,20 | 1422,40 | |

| Center to end | 95,25 | 127,00 | 158,75 | 190,50 | 222,25 | 254,00 | 285,74 | 317,50 | 342,90 | 381,00 | 441,90 |

Check the Standards and Weight Chart for Copper 90 Degree Elbows

Copper 90 degree elbows are versatile plumbing components used across various piping and plumbing applications. These elbows offer a 90-degree bend with a long radius, ensuring smooth and continuous changes in copper pipe installations.

The inherent properties of copper provide excellent corrosion resistance to the fitting, ensuring smooth water flow with minimal blockages caused by rust. This makes it a safe choice for water distribution systems.

Aluminum 90 Degree Elbow Weight Chart

| NPS (inch) | Â | Â | 01/2 | 03/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 5 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LR 90 Deg Elbow | Sch. | 5S | 0.05 | 0.06 | 0.09 | 0.13 | 0.18 | 0.3 | 0.6 | 0.9 | 1.4 | 2.9 |

| Sch. | 10S | 0.06 | 0.07 | 0.15 | 0.2 | 0.3 | 0.5 | 0.85 | 1.3 | 2 | 3.6 | |

| Sch. | 40S | 0.08 | 0.09 | 0.18 | 0.25 | 0.4 | 0.7 | 1.35 | 2 | 4 | 6.5 | |

| Sch. | 80S | 0.1 | 0.11 | 0.2 | 0.35 | 0.5 | 0.9 | 1.8 | 2.9 | 5.9 | 9.7 | |

| SR 90 Deg Elbow | Sch. | 5S | 0.03 | 0.04 | 0.06 | 0.09 | 0.12 | 0.2 | 0.4 | 0.6 | 0.9 | 1.95 |

| Sch. | 10S | 0.04 | 0.05 | 0.1 | 0.13 | 0.2 | 0.33 | 0.6 | 0.9 | 1.35 | 2.4 | |

| Sch. | 40S | 0.05 | 0.06 | 0.12 | 0.17 | 0.27 | 0.47 | 0.9 | 1.35 | 2.65 | 4.35 | |

| Sch. | 80S | 0.07 | 0.07 | 0.13 | 0.12 | 0.33 | 0.6 | 1.2 | 1.9 | 3.9 | 6.5 | |

| NPS (inch) | Â | Â | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | |

| LR 90 Deg Elbow | Sch. | 5S | 4 | 7.4 | 13.6 | 23.4 | 29 | 41.3 | 51.8 | 73 | 122 | |

| Sch. | 10S | 5 | 10 | 16.8 | 27 | 35 | 47 | 59 | 85 | 140 | ||

| Sch. | 40S | 10.5 | 21.5 | 38.5 | 59 | 70 | 95 | 120 | 146 | 210 | ||

| Sch. | 80S | 16 | 33.5 | 52.5 | 79 | 94 | 125 | 158 | 194 | 282 | ||

| SR 90 Deg Elbow | Sch. | 5S | 2.7 | 4.9 | 9.1 | 15.6 | 19.3 | 27.5 | 34.5 | 49 | 82 | |

| Sch. | 10S | 3.35 | 6.7 | 11.2 | 18 | 23.5 | 31.5 | 39.5 | 57 | 94 | ||

| Sch. | 40S | 7 | 14.5 | 25.6 | 39.5 | 47 | 63.5 | 80 | 98 | 140 | ||

| Sch. | 80S | 10.5 | 22.5 | 35 | 53 | 63 | 84 | 105 | 129 | 188 |

90 Degree Pipe Elbows are Available in Various Materials Such as Stainless Steel, Carbon Steel, and Nickel Alloys

Selecting the right material for 90 degree pipe elbows is crucial since using the wrong material can lead to issues. Using an unsuitable material may cause erosion problems that could affect the application.

90 Deg Elbow Materials

| Material | Grades | Characteristics |

|---|---|---|

| Stainless Steel 90 Deg Elbow |

|

|

| Carbon Steel 90 Degree Elbow |

|

|

| Alloy Steel |

|

|

| Duplex / Super Duplex |

|

|

| Nickel Alloy |

|

|

View the Pressure Rating and Tolerance Chart for ASME B16.9 90 Deg Elbow

Choosing the appropriate pressure rating and tolerance ensures that the system operates safely without leaks or damage. Below is a pressure rating and tolerance chart for two different materials, which will help prevent failures.

Stainless Steel 90 Degree Elbow Pressure Rating

| Temperature Ratings | (oF) | -20 to 150 | 500 | 250 | 200 | 300 | 400 | 350 | 450 | 550 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (oC) | -29 to 66 | 260 | 121 | 93 | 149 | 204 | 177 | 232 | 288 | |||

| Pressure Class | 150 | 300 | – | 225 | 265 | 185 | – | 150 | – | – | ||

| 300 | 1/4 – 1 inch. | 2000 | 510 | 1575 | 1785 | 1360 | 935 | 1150 | 725 | 300 | ||

| 1 1/4 – 2 inch. | 1500 | 450 | 1200 | 1350 | 1050 | 750 | 900 | 600 | 300 | |||

| 2 1/2 – 3 inch. | 1000 | 385 | 825 | 910 | 735 | 560 | 650 | 475 | 300 | |||

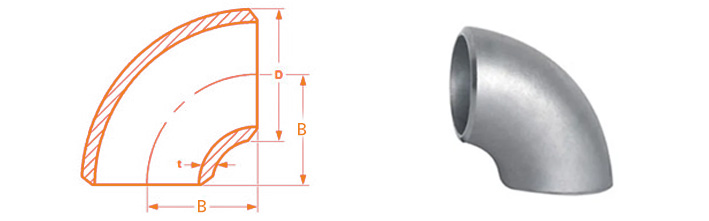

Copper 90 Degree Elbow Dimensional Tolerance

| Nominal Pipe Size | OD | at Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Nominal Pipe Size | OD | at Bevel (D) | ID at End | Center to End LR (A/B) | Center to End 3D (A/B) | Wall Thickness (t) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 to 2.1/2 | 1.6 | -0.8 | 0.8 | 2 | 3 | 10 to 18 | 4 | -3.2 | 3.2 | 2 | 3 | Not less than 87.5% of Nominal Wall Thickness | |

| 3 to 3.1/2 | 1.6 | 1.6 | 2 | 3 | 20 to 24 | 6.4 | -4.8 | 4.8 | 2 | 3 | |||

| 4 | 1.6 | 1.6 | 2 | 3 | 26 to 30 | 6.4 | -4.8 | 6.4 | -4.8 | 3 | 6 | ||

| 5 to 8 | 2.4 | -1.6 | 1.6 | 2 | 3 | 32 to 48 | 6.4 | -4.8 | 6.4 | -4.8 | 5 | 6 | |

90 Degree Elbow Angularity Tolerances

| ND | 1/2 to 4 | 5 to 8 | 10 to 12 | 14 to 16 | 18 to 24 | 26 to 30 | 32 to 42 | 44 to 48 | |

|---|---|---|---|---|---|---|---|---|---|

| Max off plane | P | 2 | 4 | 5 | 7 | 10 | 10 | 13 | 20 |

| Max off angle | Q | 1 | 2 | 3 | 3 | 4 | 5 | 5 | 5 |

4 Inch 90 Degree Elbow Chemical and Mechanical Properties

| Materials | Chemical Properties | Mechanical Properties |

|---|---|---|

| Stainless Steel |

|

|

| Carbon Steel |

|

|

| PVC |

|

|

| CPVC (Chlorinated Polyvinyl Chloride) |

|

|

Types of 90° Elbows

Short Radius 90 Degree Elbows (SR)

- Center-to-face dimension

- 1.0 X diameter

Racing Car Carbon Fiber Accessories,Abs Shell For Tool Cases,Abs Shell For Marine Equipment

Inamori Technology (Wuxi) Co., Ltd. , https://www.carbonfibrefactory.com