A Comprehensive Guide to Visual Inspections

Â

Visual inspection is one of the most fundamental and widely used methods for assessing the condition of an asset. It involves examining a structure, equipment, or system with the naked eye, often without the need for specialized tools. However, it requires trained professionals who understand what to look for during the process.

This method is essential in identifying visible signs of wear, damage, or defects that could lead to more serious issues if left unchecked. While traditional visual inspections involve on-site visits, modern technology has introduced Remote Visual Inspection (RVI) tools, allowing inspectors to gather data from a distance.

Traditionally, visual inspections required inspectors to walk around or inside an asset, such as a boiler, to examine every part visually. But with the rise of RVI, this process has evolved. Now, tools like drones and robotic cameras can collect high-quality visual data remotely, making inspections safer and more efficient.

Visual inspection NDT—also called visual testing—is just one of the non-destructive testing (NDT) methods that inspectors use. Learn more about NDT in this in-depth guide.

This guide explores the purpose of visual inspections, the industries that rely on them, other inspection techniques, and how drones are transforming the way inspections are conducted today.

Â

What Is the Purpose of a Visual Inspection?

Visual inspections are among the oldest and most trusted methods for evaluating the condition of an asset during maintenance. Their primary goal is to detect any potential issues that may require attention before they escalate into more serious problems.

For example, when inspecting an industrial boiler, an inspector might look for cracks in welds, signs of corrosion, leaks, or problems with supporting equipment. Identifying these issues early helps prevent failures and ensures the safety of both the asset and the people working around it.

In critical environments, such as power plants or chemical facilities, missing a defect could lead to catastrophic consequences. That’s why many visual inspections of high-risk assets are performed by licensed professionals following strict regulations.

Industries That Use Visual Inspections

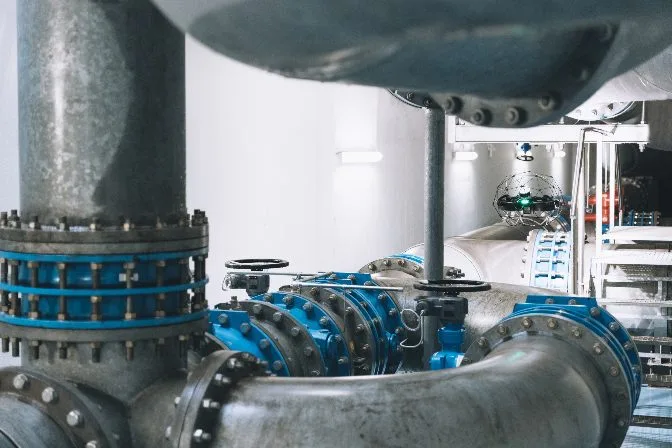

Visual inspections are widely used across various industries due to their simplicity and effectiveness in detecting flaws. Whether it's checking the integrity of pipelines, tanks, or structures, visual inspections remain a go-to method for initial assessments.

Some of the key industries that rely on visual inspections include:

- Oil & Gas

- Power & Utilities

- Chemicals

- Mining

- Maritime

- Food & Beverage

These sectors use visual inspections regularly to ensure the safety and reliability of their critical infrastructure.

Other Types of Inspection Techniques

While visual inspection is the most common method, there are several other non-destructive testing (NDT) techniques that inspectors may use depending on the situation. These include:

1. Ultrasonic Testing (UT) – Uses sound waves to detect internal flaws in materials.

2. Radiography Testing (RT) – Involves X-rays or gamma rays to identify defects within a material.

3. Magnetic Particle Testing (MT) – Detects surface and near-surface flaws using magnetic fields.

4. Acoustic Emission Testing (AE) – Monitors sound generated by material stress to detect defects.

5. Liquid Penetrant Testing (PT) – Applies a liquid to the surface to reveal cracks or other imperfections.

6. Leak Testing (LT) – Checks for leaks in vessels or structures to identify potential weaknesses.

Each of these methods has its own advantages and is used based on the specific needs of the inspection.

Remote Visual Inspection (RVI)

As we’ve discussed, visual inspections don’t always require an inspector to be on-site. With advancements in camera and robotics technology, remote visual inspection (RVI) has become a popular alternative.

RVI is particularly useful in dangerous or hard-to-reach areas. For instance, after a mine blast, it's too risky to enter the site, but a drone can safely survey the area and provide valuable visual data.

The Elios 3 flying inside a salt mine

The Elios 3 flying inside a salt mine

Similarly, inspecting large oil storage tanks can be hazardous due to the need for scaffolding. Drones eliminate the risk of falls and allow inspectors to collect high-quality data from a safe distance.

Here’s how an inspector might use RVI in practice:

- An inspector sends a drone into a boiler to capture all necessary visual data.

- The collected footage is reviewed to identify any potential issues.

Even though the inspection is conducted remotely, it still follows the same principles as a traditional visual inspection, just through digital means.

Drone footage of a damaged wind turbine that was struck by lightning

Drone footage of a damaged wind turbine that was struck by lightning

Home and building inspections are also benefiting from remote inspection technologies. Using video calls, inspectors can conduct virtual walkthroughs and assess conditions without being physically present.

How Drones Enhance Visual Inspections

Drones are becoming a preferred tool for remote visual inspections due to their flexibility, safety, and ability to capture high-quality data. They allow inspectors to access areas that would otherwise be difficult or dangerous to reach.

Tools like Flyability’s Elios 3 offer advanced features such as oblique lighting, which helps inspectors better understand the depth and texture of surfaces, even when not physically present.

Using drones for visual inspections offers several benefits:

- Safety – Reduces the need for inspectors to enter hazardous environments.

- Cost Savings – Eliminates the need for scaffolding and reduces downtime.

- High-Quality Data – Captures detailed images and videos that can be stored and analyzed over time.

With continuous improvements in drone technology, the future of visual inspections looks even more promising, offering greater efficiency and accuracy in maintaining critical infrastructure.

Â

Scented Oil Diffuser,Essential Oil Diffuser,Best Essential Oil Diffuser,Aroma Oil Diffuser

Guangzhou Chiyang Scent Technology Co., Ltd. , https://www.diffuserscent.com